UHMW is ultra high molecular weight (UHMW) polyethylene bar that has exceptionally high abrasion and impact resistance properties. It will outwear all other materials, including metals, nylons, urethanes and fluoroplastics. In corrosion resistance, it has the same qualities of other polyethylene plastics. UHMW resists wear, friction and corrosion and thus it cuts maintenance costs, energy consumption and extends equipment life. Applications for UHMW materials include guide rails, wear plates, rollers, conveyor augers, bin and hopper lines, chutes, bearings, bushings and gears.PTFE is a very useful material because it has a unique combination of properties. PTFE is chemically inert, weatherable, excellent electrical insulation, high temperature resistance, a low coefficient of friction and non-adhesive properties. Shrinkable tubing is also used as roll covers and to protect electrical parts or components. PTFE can also be skived or extruded into tapes and films that can be used for seals and gasket materials.

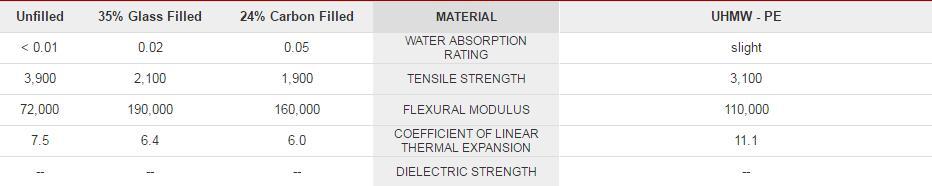

Comparison of Polymer PTFE/FEP and UHMW Property Values

Material Applications

Polymer PTFE/FEP:Cabling solutions;Non lubricated bearings;O-rings;Seals;Capacitors;Semiconductor manufacturing;High temperature electrical parts;Gaskets;Valve components.

UHMW:Starwheels;Guide Rails;Bushings;Wear plates;Bearings;Bumpers;Chain Guides;Wear strips;Sprockets.

Material Properties

Polymer PTFE/FEP:Excellent dielectric properties;Inertness to most chemicals;High heat and chemical resistance;Very low coeffiecient of friction;Excellent radiation resistance;Zero moisture absorption;Relatively insensitive to power frequency;Machinability.

UHMW:High impact strength;Machinability;Low coefficient of friction;Self-lubricating;Chemical resistant;Zero water absorption;High abrasion resistance.

Post time: Aug-04-2018